Product

HOME > Product

UV EQUIPMENT

UV PowerMAP and UV MAP Plus (단종)

본 제품은 미국 EIT사에서 더 이상 생산을 하지 않는 제품입니다. 단 제품의 검교정 및 A/S 는 가능합니다.

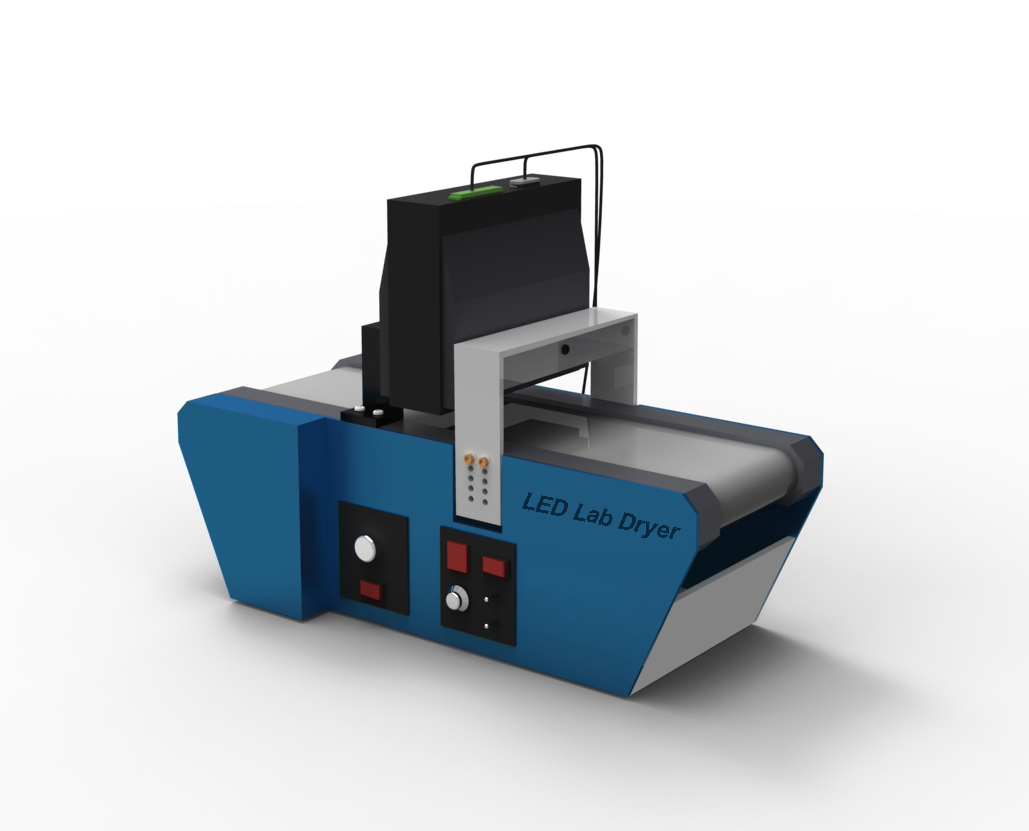

These profiling and temperature measurement systems travel through a UV system and collect data on peak irradiance (W/cm²) and energy density (J/cm²) as well as temperature. The collected i

These profiling and temperature measurement systems travel through a UV system and collect data on peak irradiance (W/cm²) and energy density (J/cm²) as well as temperature. The collected i

|

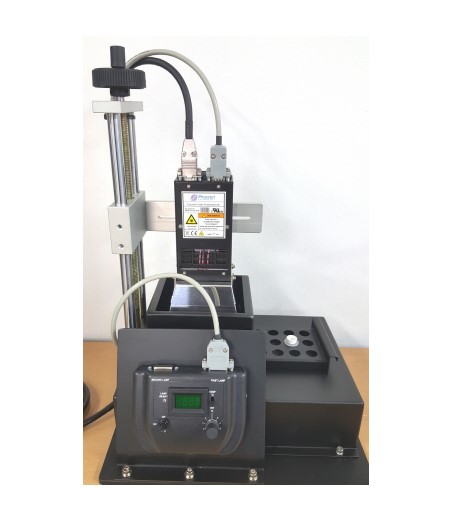

UV PowerMAP and UV MAP Plus™ Features

Both instruments feature: - User adjustable sampling rates from 128 to 2048 samples/second. The faster sample rates ensure high resolution and repeatability even at higher process speeds

- Easy to use PowerView™ software program that displays collected data in graphical and tabular forms. The PowerView™ software allows the user to also compare two different files - Detachable Optics Head that allows the use of different optics heads with a single Data Collection Unit- (UDC). This feature minimizes downtime during re-calibration and allows a single UDC to use low and high power optics heads. Users that start with a single channel UV MAP Plus™ Optics Head have the ability to upgrade to the four channel UV PowerMAP? as their needs and measurement requirements change. - Collection and storage of up to one million data points for accurate UV and temperature mapping in your system - Offset optics allow easy measurement at conveyor edge - Type J thermocouple records temperatures from 0-500oC - Low, narrow profile to allow access to most curing applications - Rugged aluminum chassis and stainless steel case Applications

- Document, measure and maintain the performance of an individual UV system or entire manufacturing line from start to finish - Document, measure, confirm and maintain the spatial geometry and original design specifications of your UV system. Easily evaluate lamp-bulb configuration and focus, reflector shape, and focus and reflector efficiency - Compare reflector materials and shapes, wavelengthspecific degradation, and uniformity over time or to other systems - Easily identify the type of bulb in the system. Compare spectral output, degradation, and uniformity of one or more UV lamps. - Measure and document substrate temperatures during the cure process to prevent damage to temperature-sensitive materials - Track and store data for statistical quality control, regulation compliance or historical comparisons - Print run data to attach to work orders, reports, or quality audits - Archive measurement data to track system performance over time     |